Understanding Cloud ERP for Manufacturing

Cloud ERP systems are transforming how manufacturing businesses manage their operations. These systems provide enterprise resource planning applications through the Internet that let you access business data and functions from any web browser.

Your manufacturing operations can get several important benefits from cloud ERP:

- Enhanced Accessibility: You can view vital data anywhere using smartphones, laptops, or tablets

- Real-time Integration: A centralized system connects all your manufacturing processes

- Automated Updates: Software updates happen automatically without IT support

- Scalable Resources: Your system grows as your business expands

- Improved Security: Enterprise-grade security measures protect your data effectively

A cloud manufacturing ERP gives you clear visibility into your operations. The platform combines inventory management, production schedules, quality control workflows, and customer relationship management. This integration helps you make better decisions based on up-to-the-minute data analysis.

Modern cloud-based ERP systems come with artificial intelligence and automation capabilities that make your manufacturing processes more agile. These features optimize operations and boost productivity throughout your organization. The system automatically orders supplies when inventory gets low and adjusts production schedules based on current demand.

Cloud ERP systems use a subscription model that keeps costs predictable without large IT infrastructure investments. You can focus your resources on manufacturing instead of managing complex IT systems.

Key Factors to Consider When Choosing a Cloud ERP

Choosing a cloud ERP system for your manufacturing business requires careful evaluation of key factors that will help you make the right choice. Your chosen solution should grow naturally with your business without needing major changes or new investments to match your scalability needs.

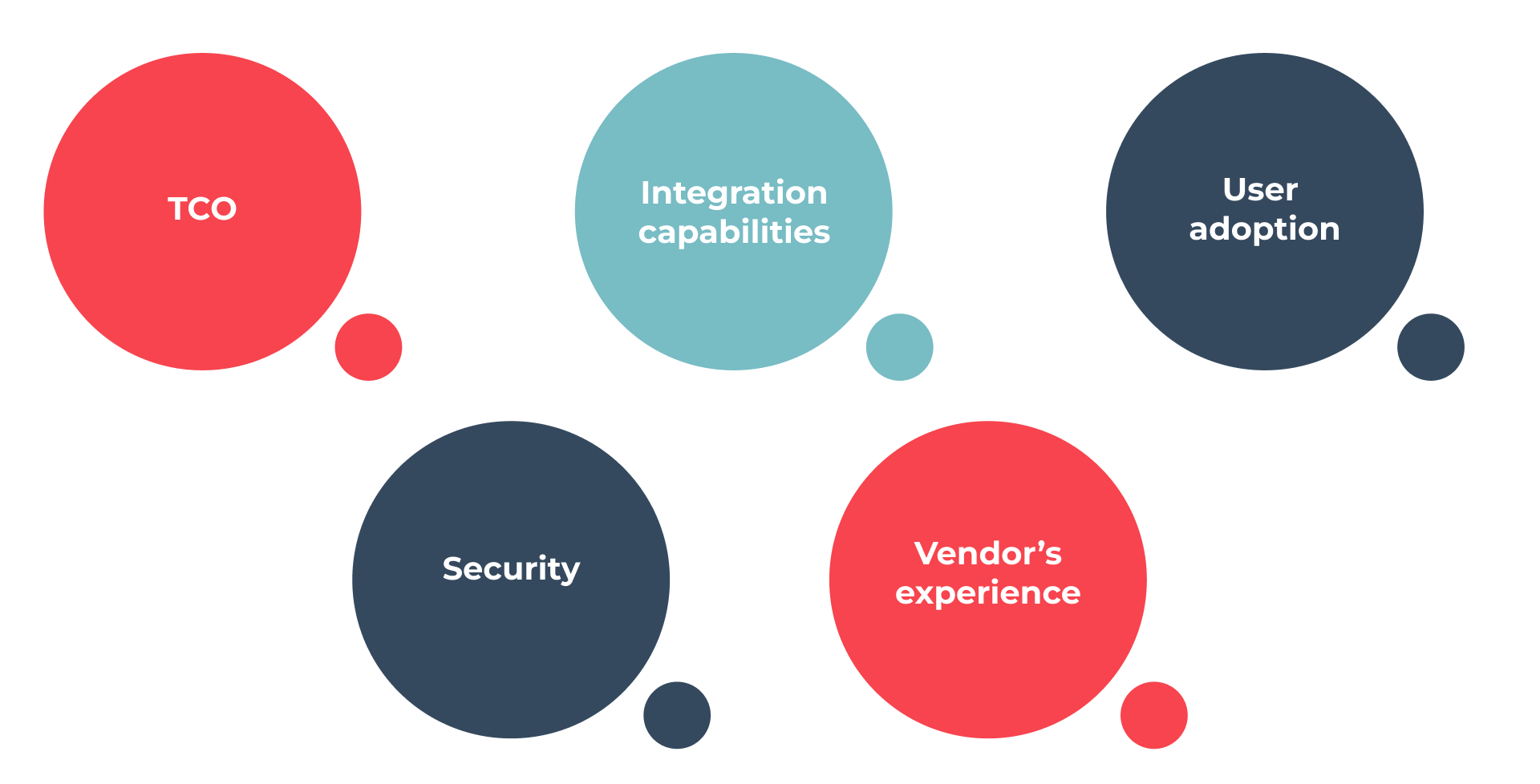

Here are the most important evaluation criteria:

- Total Cost of Ownership (TCO): Add up direct and indirect costs for five years, which includes implementation, training, and maintenance

- Integration Capabilities: The system must blend with your existing applications and manufacturing processes

- User Adoption: Find systems with easy-to-use interfaces and detailed training support that ensure smooth implementation

- Security and Compliance: Check the vendor’s security measures and compliance certifications for manufacturing

- Vendor Experience: Pick providers that have deep manufacturing expertise and proven results

Your manufacturing ERP software should give you flexible deployment options and work with multi-tenant or single-tenant setups based on what you need. The system’s immediate data analytics and reporting features will give you an edge in making informed decisions.

The vendor’s implementation approach matters a lot. Agile methods work better than traditional waterfall approaches and help your team learn step by step. A good cloud manufacturing ERP should let your staff check important information from anywhere in your facility through mobile access.

Implementation Best Practices

Your cloud ERP system needs proper planning and execution to work well. A strong change management strategy should come before any technical work begins. The success of your implementation depends on how well you prepare your organization for this change.

Here are the key steps you need to take:

- Design a complete training program that fits different user roles

- Create a clear data migration plan with data cleaning steps

- Build a Target Operating Model to support after going live

- Add ways to keep improving as system updates come

- Schedule regular checks and tweaks to optimize performance

Your data migration needs extra care during implementation. You should check, extract, and clean your data before moving it to the new cloud manufacturing ERP system. This approach stops disruptions and keeps your manufacturing data accurate.

Training plays a vital role in getting the most from your cloud ERP system. Your role-based training should focus on real tasks that each department handles daily. Note that good training goes beyond the original setup – you need ongoing learning as your system grows.

Support after implementation will determine your long-term success. The Target Operating Model must define clear governance, support steps, and who does what. This structure helps your manufacturing business handle updates and improvements while staying efficient.

Conclusion

Cloud ERP systems help manufacturing businesses tackle complex challenges through detailed operational management and immediate data insights. Manufacturers can position themselves for long-term growth and operational excellence by choosing the right system based on flexibility, integration features, and vendor expertise. Modern cloud ERP tools streamline production processes, boost quality control, and allow quick responses to market shifts.

The right cloud ERP system gives manufacturing businesses the agility and understanding they need to succeed in today’s ever-changing manufacturing environment.